Making money with rabbits

Farmers can rear a few rabbits at low cost and produce a fair quantity of wholesome and tasty meat. There are many reasons Why raising rabbits is a worthwhile venture.

But to raise rabbits successfully they must begin with healthy animals, provide a good hutch, clean and nutritious feed and take good care of them.

Management Systems

Rabbits like other domestic animals, may be bred and reared at various intensities.

|

|

Feed time between kindling and mating |

||

|

Extensive Greens 8 – 10 weeks |

Semi-intensive Greens/concentrates 4-6 weeks (or re-mating 1 – 2 days after weaning) |

Intensive Concentrates 1 – 2 weeks |

|

|

Age of young at weaning |

8 – 10 weeks |

6 – 8 weeks |

4 – 5 weeks |

|

Number of litters per doe, year |

3 – 4 |

5 – 6 |

8 – 10 |

|

Number of young weaned per doe, year |

10 – 20 |

30 – 40 |

50 – 65 |

|

Age of young at slaughter |

20 – 30wks |

12 – 15 wks |

10 – 13 wks |

|

Daily grain during fattening |

10 – 15g |

20 – 30g |

25 – 30g |

|

Production of cold dressed meat per doe, year |

15 – 25kg |

40 – 60kg |

75 – 100kg |

You can mate rabbits just about any time of the year. The doe usually kindles 30 – 32 days after mating. Check the doe for pregnancy 10 days after mating and if not pregnant, it should be mated again. A shortened interval between kindling and mating increases the number of litters per doe per year. Commercial producers should aim at getting 42 kids per doe per year i.e. at least 6 litters per year with 7 kids weaned per litter.

With intensive production the breeding doe should be replaced every one to 1.5 years, while in a semi-intensive system, she may last 3 years. Replacement does are bred for the first time at 5 months of age.

In semi-intensive systems a substantial part of the diet for rabbits consist of greens, such as grass, browse, weeds, vegetable waste, roots, tubers and vegetables. This normally means longer breeding interval and results in lower daily gain than intensive systems where the rabbits are fed with only rabbit pellets or chicken mash. But since the feeding cost is lower, large profits for the rabbit farmer can be realized.

Housing

Hutches

While there are many types of hutches, there are certain essential features that any well designed hutch should provide:

- Enough space for the size of the rabbit

- Fresh air and light, but excluding direct rays of the sun

- Protection from wind and rain

- Sanitary conditions and ease of cleaning

- Sound but cheap construction, which is free of details that could injure the animals

- Convenience of handling

- A cage for each adult rabbit

Space requirements

Each adult rabbit must have its own cage or compartment. Depending on the rabbit breeds, domestic rabbits vary in weight from 2 to 7kg. The size of cages is determined by allowing 1200 to 1500 cm2 of clear floor space per kilo of adult weight. This means that a cage for a medium breed buck should be a minimum of 80cm x 80cm. On the other hand, cages for females should allow extra space for the nest box and the litter, hence 80cm x 115cm should be regarded as minimum for a medium breed doe.

Young rabbits reared for meat can be kept in groups of up to 20 to 30 animals until they reach four months of age. Weaners that are kept in one group should be about the same age and weight. Such colony pens should allow 900 to 1200 cm2 floor space per kilogram of liveweight.

The cages should not be deeper than 70 to 80cm for ease of reaching a rabbit at the back of the cage. The floor to ceiling height of the cage should be a minimum of 45 to 60cm and it is vital to have the floor of the cages 80 to 100cm off the ground to handle the rabbits comfortably.

Hutch modules

Any size rabbit unit can be made up of two-doe or four-doe modules. The number of cages required in each of these modules is shown in the table below.

|

|

Cage for buck |

Cages for does |

Cages for fattening weaners |

Total number of cages per module |

|

2 doe module Extensive production Semi-intensive production Intensive production |

1 1 1 |

2 2 2 |

(1) 1 2 |

3 (or 4) 4 5 |

|

4 doe module Semi-intensive production Intensive production |

1 1 |

4 4 |

3 4(to 5) |

8 9 (or 10) |

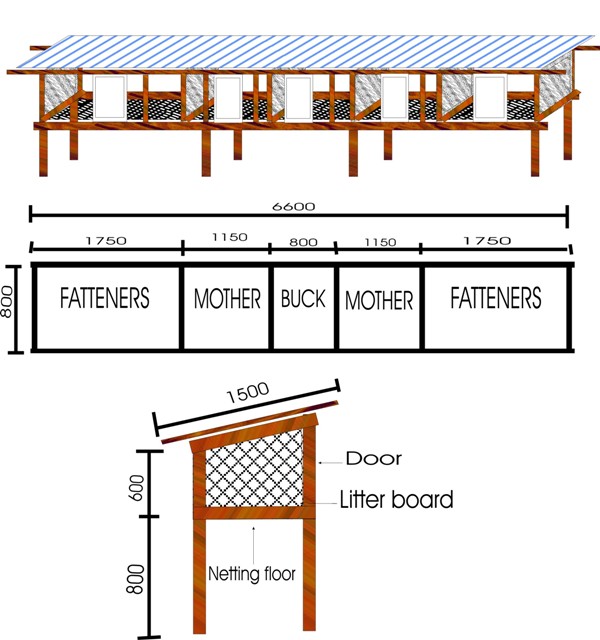

The small scale rabbit producer can have one such module, covered with its own roof, placed directly on the cages as shown.

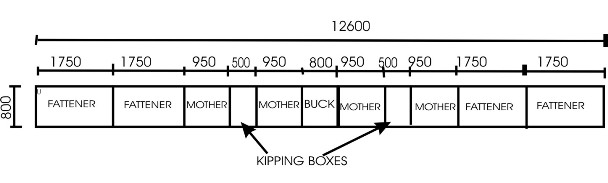

Plan view of rabbit housing module for 4 does, 1 buck and fatteners. Kindling boxes are permanently installed with access from each cage for a doe. The kindling boxes have outside doors to facilitate cleaning. The cross section is similar to the one shown above.

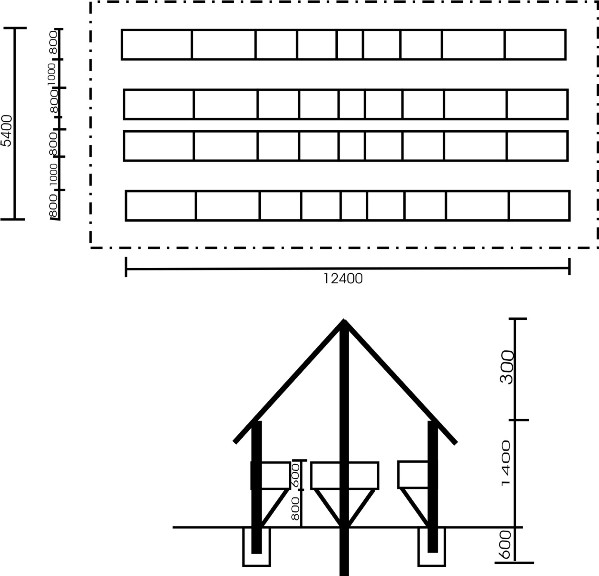

The medium to large rabbit producers can have several modules placed under a separate roof or in a shed as shown here.

Construction details

Proper ventilation of the rabbitry is essential. The walls, roofs and door of the hutch can be covered with chicken wire netting (37mm mesh) or made up of wood or bamboo placed 20mm apart.

In high altitude areas with lower temperatures it may be desirable to have a solid wall in the direction facing the prevailing wind. Temporary protection for strong winds, low temperatures and rain can be provided with curtains of hessian, reeds, grass, and plastics etc. The roof of the rabbit unit should be leak-proof and can be made of thatch or metal sheets with some insulation underneath.

Ease of management depends to a great extent on the construction of the floor. It may be solid, perforated, or semi-solid. Each has its advantages and disadvantages.

A solid floor can be made from wood, plywood or different kind of boards. It allows bedding to be used, eliminates draughts through the floor and causes less trouble from hock sores, but difficult to clean. The use of a solid floor will permit the hutches to be stacked in two or three tiers with the bottom row 30cm off the ground, and this may save some building space. However, a solid floor in the hutch frequently lead to outbreak of coccidiosis, loss of appetite and often death, because of build up of manure in corners of the cage and contamination of feed and water.

A perforated floor is self-cleaning as manure and urine pass through to the ground and this assist in disease control, but if not properly constructed it may injure the animals. It can be made of woven or welded wire of not less than 16 gauge. Suitable mesh sizes are 12mm for small and medium breeds and 18mmm for large breeds. Chicken wire can be used, but its thin wires may cause sore hocks and the urine can corrode the wire to failure within a year. The wire netting is stretched over a wooden frame, trimmed flush with the bottom edge, and stapled every 5cm. where it is fastened to post the wire edges should be turned down to avoid injury to the rabbits. Self cleaning floor is usually recommended.

Equipment and store

Drinkers

A doe with litter require up to 5 litres of water per day if fed only on rabbit pellets or chicken mash. Rabbits receiving fresh greens daily will require less water, but all rabbits should have access to clean drinking water at all times.

An automatic waterer can be made from a large bottle and a small tin can. Fasten the bottle to the inside of the hutch so that the lip of the bottle is about 1cm below the rim of the can. Fill the can and the bottle with water and replace the bottle. As the rabbit drinks from the can, the water will be replaced from the bottle.

Alternatively a nipple drinker from a bottle, a pierced rubber cork and a piece of 6 to 8mm steel pipe as shown. This allows the bottle to be placed outside the cage for easier refilling and there is less risk of contamination of the water as the rabbits drink by licking the nipple.

Feeders

Heavy earthenware pots, about 8cm deep and 10 to 15 cm diameter make good dishes for feeding grain, pellets and mash because they are not easily tipped over. Tin cans, free of sharp edges, or open sections of bamboo nailed to a small board can also be used. However, rabbits like to a scratch out feed with their feet and to avoid this, a feed hopper which is tied to the side of the hutch, can be made from an empty 5 litre tin. A 6 by 12cm flap is cut 6cm from the bottom and straightened with a piece of timber and then bent inwards. The top of the tin is removed and the edges bent flat against the inside of the tin.

A manger made out of a piece of wire mesh, 40cm x 40cm, can be fixed to the door of the cage for feeding greens or hay. This allows the rabbit to pull forage into the cage as it increases the risk of disease. The remains of greens left on the floor must be removed every day.

Nests

Does like to kindle in a private place. A nestbox should be placed in the doe’s cage 5 to 7 days before birth. A box for medium sized breeds should be about 30cm wide, 40 to 50cm long and 20 to 30cm high. A lid is sometimes supplied as some does prefer the nestbox to be dark and in cold weather the lid will conserve some heat for kids. Straw or grass lining of the box is generally not necessary but will provide extra protection in cold weather. The box can be made of plywood, hardwood, wooden planks or even bamboo, but whatever is used it must be easily cleaned.

Feed storage

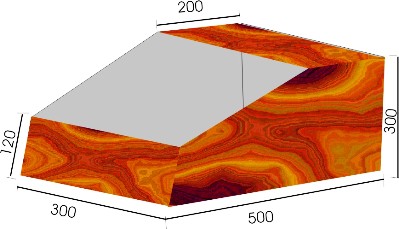

The storage requirement for feed to all categories of animals in a rabbit unit can be determined by multiplying the following figures with the number of does in the unit and the number of days in the storage period:

In intensive production each doe-unit requires 1.3 to 1.8kg pellets or mash per day.

In semi-intensive production each doe-unit requires 0.3 to 0.5kg pellets or mash per day. No storage is required for greens as they should be fed fresh every day, but if hay is used instead of greens each doe-unit will require 0.1 to 0.15kg per day.

Feeding

A balanced diet fed in adequate amounts, good sanitation, disease control, appropriate housing and equipment and good care are all important factors when aiming at lower mortality and higher daily gain.

The mortality in a well managed rabbit unit should be below 20% from birth to slaughter among the young and below 20% annually among adults, but presently many producers in Kenya experience mortality of up to three times that.

Gross Margins (Intensive Rabbit Meat Production)

Production costs depend on the system of production. Feeds constitute the major cost. Extensive systems are less costly as less commercial feeds are used but the profit margins and turn over rates are also minimal. We are going to calculate our gross margins based on intensive systems where commercial pellets are fed.

Rabbits consume about 25g of pellets per day which convert to 2.25 Kg in 90 days. At 90 days the dressed weight will be between 1-1.2kg. Meat is sold at between Kshs 500 and 600 per kilogram dressed weight.

|

|

2 does and 1 buck Ksh |

4 does and 1 buck Ksh |

|

Gross output |

|

|

|

Sale of rabbits at Ksh 500 |

84 weaners at 500 is Ksh 42,000 |

168 weaners is Ksh 84,000 |

|

|

|

|

|

Variable cost |

|

|

|

Purchase of breeding stock at Ks 2500 each |

7,500 |

12,500 |

|

Feeds |

6 bags at Ks 1200 per bag is 7,200 |

12 bags gives Ksh 14,400 |

|

Veterinary care |

2000 |

3000 |

|

Labour |

12000 |

12000 |

|

Depreciation of the house |

1000 |

1000 |

|

Transport |

1000 |

1000 |

|

Total variable cost |

30,700 |

43,900 |

|

|

|

|

|

Gross margin |

11,300 |

40,100 |

Note that the prices of rabbit meat have frequently fluctuated and sometimes as low as Ksh 300 or as high as Ksh 1000 a kilo in some places. To maximize the profit, the farmer is well advised to raise breeding rabbits s their price are far much higher. on average prices for breeding rabbits range between ksh 1500 and 2500 per animal and in some cases it has gone hs high as ks 5000. If you convert these figures from meat to breeding animals then you will be talking of gross margins over 100,000 and 220,000 for a 2-doe unit and 4-doe unit respectively. You will also notice that the economies of scale are more pronounced when more rabbits are raised.

Markets

So far there are no formal markets as in milk where you sell through cooperatives or directly to processors. But due to the increasing popularity of rabbit meat private slaughter houses are coming up. An example in point is two rabbit meat butcheries in Gilgil and Murang'a towns and a planned abattoir in Kiambu County. A restaurant specializing in rabbit meat is also in Murang'a town. Meanwhile the government is in the process of establishing NEMA certified slaughter houses in various parts of the country.

But as you wait for formal marketing channels you can still use the existing ones. Rabbit farmers have sold the meat to local restaurants and supermarkets and you can also do the same. On the other hand you can opt to export but the biggest problem with exporting rabbits has been the export volumes. Our production is so low that we cannot meet the export demand.To benefit from exporting these products rabbit farmers must join cooperatives to pool resources and take advantage of economies of scale.

Last but not least, don't fear to look for markets for your products. Formal markets where everyone flocks to are known to have lower returns compared to niche markets where there are few sellers and therefore higher prices. Strive to look for a niche market of your own and you could just make a killing.

Comments

RSS feed for comments to this post